With passengers once again left frustrated by rail delays and disturbance over the Easter period, UK rail operators will no doubt face further scrutiny over the quality of service they are providing commuters. With services frequently disrupted by signalling problems, broken-down trains and congestion, the industry, the Government and, of course, consumers all recognise that something needs to change.

One technology that is starting to be used to address this challenge is Big Data through Predictive Maintenance (PM). This is a solution that has come to the forefront thanks to the recent advancements in sensors and communication technologies in trains. These sensors, embedded into various systems and subsystems in trains, generate huge volumes of data, which can be collected and analysed 24 hours a day, seven days a week. This helps operators identify looming faults, forecast the optimal time for maintenance and, ultimately, enable them to predict conditions that could become a hurdle in the future and tackle them early, before service is affected. The success that this technology has already had, has led it to fast become one of the most sought after MRO (maintenance, repair and overhaul) strategies in the industry.

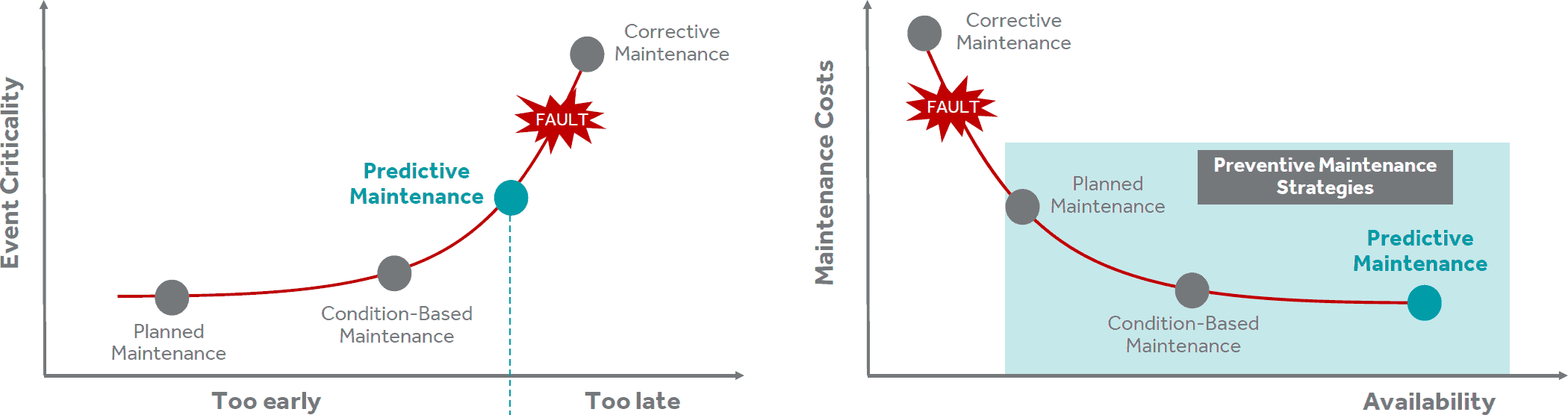

As shown in Figure 1, big data analytics helps to predict the optimal timing for maintenance. In most instances, the process becomes very costly, but if it is reactionary, the implications could be far worse. If looming faults are identified proactively, not reactively, then necessary maintenance work can be started just before a fault occurs, maximising the efficiency of the process.

Figure 1: The optimal maintenance timing: higher availability and lower maintenance costs

Today’s technology makes it possible to affordably collect huge amounts of data from hundreds of systems in a single train, analyse that data in real-time and detect problems before they actually happen. This detailed overview provides much greater visibility, both on the vehicle as a whole, and at a more granular component level. It’s this insight that allows maintenance activities to be planned with the maximum interval between repairs, while minimising the number and cost of unscheduled outages created by system failures.

The benefits of using data in rail

PM enhances the overall effectiveness of transportation systems, ultimately leading to improved safety and higher customer satisfaction, something which is incredibly important when there’s such a spotlight on the network operators.

Affordable solutions can generate ROI quickly while completely transforming the maintenance landscape. Computing systems are evolving rapidly to on-board intelligent systems without taking data to any remote cloud. However, these technologies are new and, as such, immature within this sector.

Taking learnings from other industries, such as aerospace, train operators and OEMs should follow these five steps to deploy data analytics and PM successfully. Each stage is crucial to successively ensuring that prediction is possible and that it can be implemented into the maintenance scenarios previously discussed:

1) Choose the right system or subsystem for prediction

Selection of the system is the most critical step in building a PM solution. It is crucial to define a narrow scope and not try to predict everything. Doors would be a typical example of such systems.

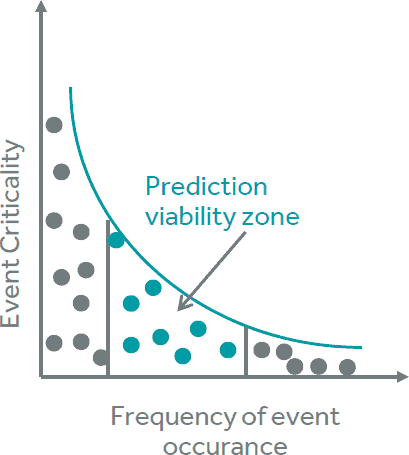

It is therefore important to identify what is possible to predict. You can do this by mapping the available systems into a “prediction possibility zone” and a “prediction effectiveness zone” (as shown in Figures 2 and 3).

The latter of these is particularly dangerous, as organisations could potentially make the mistake of dismissing a vital solution that they have a clear need for, simply because they did not appropriately select the original parameters it was required to cover.

The prediction possibility zone

The objective here is to predict the failure of the most critical systems. However, such systems run the risk of leaving very little data to build any consistent model. Conversely, there is limited value in predicting the failure of less “vital” systems, even if they produce a wealth of data.

It is important to select the critical events that leave enough of a digital footprint that is required to build a consistent and reliable predictive model. In essence, a system has to fail enough to reveal the pattern, but it must equally be important enough to be worth predicting in the first place. So the prediction possibility and viability zone is somewhere in between those limits of frequency of occurrence and event criticality. As shown in Figure 2, an ideal system or subsystem has to be chosen for building the PM solution based on the prediction possibility zone.

Figure 2: Prediction possibility zone

Prediction effectiveness zone

Another way to look at system selection is to find where prediction is more effective from a maintenance point of view. The failure rate of mechanical and electrical systems typically follows a bathtub curve (as shown in Figure 3).

Figure 3: Bathtub curve: Hypothetical failure rate versus time

In order to realise quick ROI, either early life or end-of-life systems are more suitable for deploying PM solutions, as you will derive the greatest benefit from predicting their failure.

2) Identify the required data sets as early as possible

It is generally assumed that the sheer volume of data generated from systems is sufficient to build PM solutions from it. However, it is important to remember the objectives behind collecting each data set. They may have been deployed by the manufacturer without any PM solution in mind.

As such, preparing the data required for building PM solutions is one of the key activities in the process of solution development. It is not always what operators already have, but it’s about what the solution needs. A fair understanding of the objectives is necessary to come up with the required data sets.

Taking a top-down approach often leads to a successful outcome here. This is where the business objectives are clearly defined first, before the required data sets are identified, and then the data is prepared in order to develop an algorithm.

3) Identify the value-add of PM for maintenance strategies

The scope of a PM solution can go beyond merely predicting a failure, since in most situations; prediction is not the only objective. It’s also about identifying various business scenarios and building appropriate prescriptive actions.

Therefore, an effective PM solution should also support the maintenance teams in planning the inventory for replacement of parts and suggesting which systems need an upgrade in their design due to their continued poor performance. This is possible by understanding the reasons behind various failure patterns and categorising them into various action buckets. As such, PM solutions address both short-term and long-term objectives.

4) Complement your data science team with rail expertise

Bolster your data scientists’ understanding with knowledge of the rail sector. It is generally assumed that a data scientist is all that is needed to build a cutting-edge algorithm for a PM solution. A data scientist can develop any algorithm, but it takes a lot more to deliver the right algorithm for a specific business need. Experience shows that it is the domain expert, as opposed to the data scientist, that is the real hero in achieving a successful solution, as they can guide the data scientist to build the right algorithm. Interpretation of patterns – vibration and noise for example – is a key area where the rail expert can guide the data analyst as to not over-interpret coincidence findings.

5) Look for the right skills when hiring data scientists

Finally, as big data analytics is an industry that’s still in its infancy, particularly in the rail sector, it’s incredibly important that individuals with the right skills and experience are brought on board as quickly as possible. When hiring junior level developers, look for those with a general understanding of analytics and basic knowledge of java programming. This makes it easier to train them in Hadoop-based programming. For senior level roles, look for a strong technical background in analytics with matching exposure to the transportation domain.

Predictive Maintenance in Rail

As big data analytics looks to establish its position in the rail industry, operators should look to successes already gained in other sectors to deploy effective solutions. It is already a mature and proven concept elsewhere and there is no reason why the rail market cannot reap the same derived benefits. The success of PM lies in the selection of the right systems, creating and preparing the necessary data, and getting the right combination of rail experts and data scientists on board. Combine those and you have a winning formula.

In addition, OEMs should look to PM to deliver beyond mere prediction of failures; to identify those systems that need design upgrades, for instance. Ultimately, besides increased availability and cost efficiency, commuters will appreciate fewer delays and increased safety, resulting in higher customer satisfaction.

Bhoopathi Rapolu is the Head of Analytics, EMEA at Cyient. In this role, he is responsible for customer engagement, solution development and business development. He has over 15 years of experience in business Intelligence and technology management, and has spent the last few years evangelising about the integration of Operational Real-Time technologies with IT technologies. He has conceptualised and delivered intelligent asset management solutions powered by telematics and advanced analytics primarily for Aerospace, Transportation, Heavy Equipment, Utilities and Telecom. He has also built and run large BI systems and has delivered enterprise-level solutions for advanced functional and operational analytics platforms.

Bhoopathi Rapolu is the Head of Analytics, EMEA at Cyient. In this role, he is responsible for customer engagement, solution development and business development. He has over 15 years of experience in business Intelligence and technology management, and has spent the last few years evangelising about the integration of Operational Real-Time technologies with IT technologies. He has conceptualised and delivered intelligent asset management solutions powered by telematics and advanced analytics primarily for Aerospace, Transportation, Heavy Equipment, Utilities and Telecom. He has also built and run large BI systems and has delivered enterprise-level solutions for advanced functional and operational analytics platforms.

Photo credit: Nick Kenrick . / Source / CC BY-NC-SA