What is IIoT? Imagine a world where machines and devices can communicate with each other in real-time, exchanging data and insights to optimize industrial processes and improve efficiency. This is the world of the Industrial Internet of Things (IIoT).

IIoT is a transformative technology that is revolutionizing the way that industrial organizations operate, enabling them to gain a competitive advantage in today’s rapidly changing business landscape. From predictive maintenance to remote monitoring, IIoT systems provide a range of tools and services that enable organizations to optimize their operations and reduce costs.

What is IoT?

IoT, or the Internet of Things, refers to a network of physical objects, devices, vehicles, buildings, and other items that are embedded with sensors, software, and connectivity, enabling them to collect and exchange data with other devices and systems over the internet.

What is IIoT?

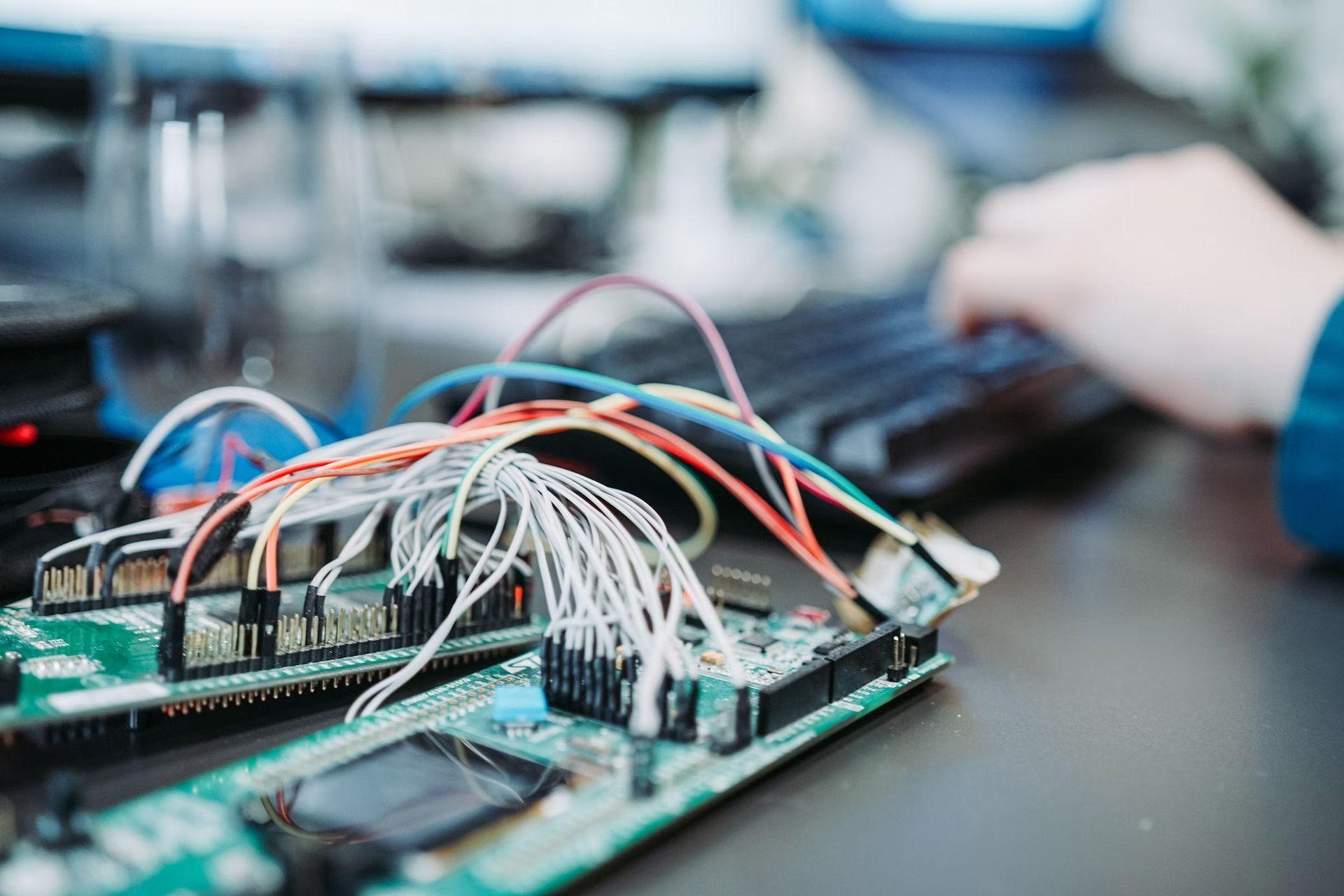

The Industrial Internet of Things is a term used to describe the integration of physical industrial devices with network connectivity and software applications. It involves the use of sensors, embedded systems, and other hardware devices that are connected to the internet to gather and exchange data. The data collected from these devices is analyzed in real-time to provide insights that help organizations optimize their operations, increase productivity, and reduce costs.

The IIoT represents a significant shift in the way that businesses operate, as it enables a higher level of automation, control, and visibility over industrial processes. The integration of IoT devices with traditional industrial systems has also led to the development of new business models, such as predictive maintenance and remote monitoring.

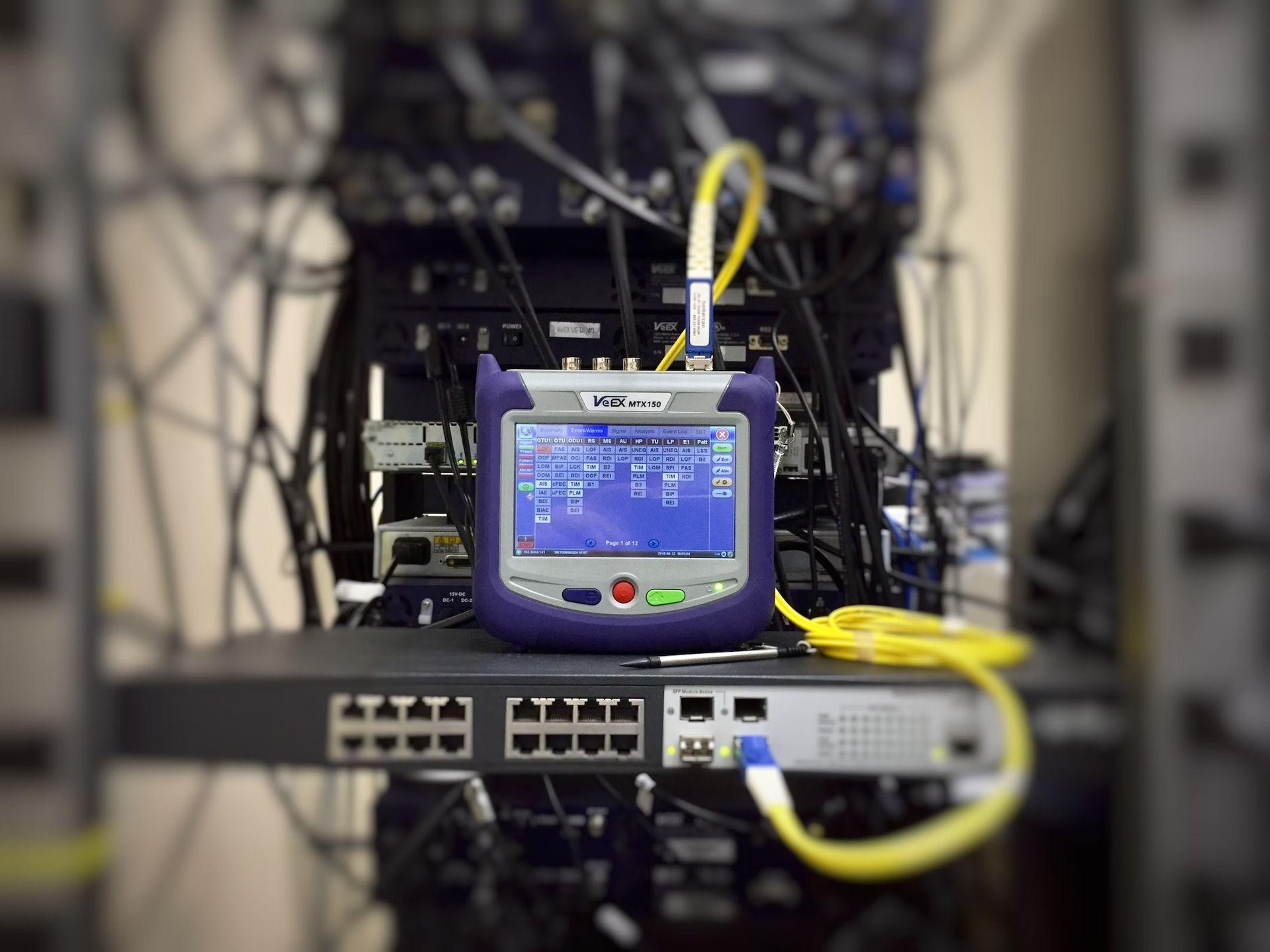

Understanding IIoT architecture

The architecture of the IIoT refers to the design and organization of the various hardware, software, and networking components that make up an IIoT system. A typical IIoT architecture consists of three layers: the edge layer, the platform layer, and the enterprise layer.

The edge layer is where the sensors and other IoT devices are located. These devices collect data and transmit it to the platform layer for processing. The platform layer is responsible for managing the data and providing services such as data storage, analytics, and visualization. The enterprise layer is where the insights generated by the IIoT system are used to make decisions and drive business outcomes.

Building trust in IoT ecosystems: A privacy-enhancing approach to cybersecurity

An IIoT system also requires a range of communication protocols to enable the different components to interact with each other. These protocols include Wi-Fi, Bluetooth, ZigBee, and other wireless standards, as well as wired standards such as Ethernet.

The architecture of an IIoT system can vary depending on the specific requirements of the application. However, regardless of the specific implementation, an effective IIoT architecture must be scalable, secure, and reliable, as it is often used to support mission-critical industrial processes.

Types of IIoT

There are several types of IIoT systems, each with its own unique characteristics and applications. Some of the most common types of IIoT include:

- Condition monitoring systems (CMS): These IIoT systems are designed to monitor the condition of equipment and machinery in real-time, using sensors and other IoT devices to collect data on factors such as temperature, vibration, and fluid levels. This data can be used to predict when maintenance is required, reducing downtime and increasing efficiency.

- Predictive maintenance systems: Similar to CMS, predictive maintenance IIoT systems use data from sensors to identify potential issues with the equipment before they occur. By analyzing patterns in data, these systems can predict when a component is likely to fail and schedule maintenance accordingly.

- Remote monitoring systems: IIoT systems can be used to monitor industrial equipment and processes remotely, allowing operators to keep an eye on their operations from anywhere in the world. This can be particularly useful for monitoring equipment in remote locations or for monitoring equipment that is difficult or dangerous to access.

- Process optimization systems: IIoT systems can also be used to optimize industrial processes by gathering data on factors such as temperature, pressure, and flow rate and using this data to adjust process parameters in real-time. This can improve efficiency, reduce waste, and improve product quality.

- Asset tracking systems: IIoT systems can be used to track the location of industrial assets, such as vehicles, containers, and equipment, using GPS and other tracking technologies. This can help to improve logistics, reduce the risk of theft, and improve asset utilization.

- Energy management systems: IIoT systems can be used to monitor and optimize energy usage in industrial facilities by gathering data on factors such as energy consumption, temperature, and lighting levels. This can help to reduce energy costs, improve sustainability, and comply with environmental regulations.

IIoT systems offer a wide range of benefits to industrial organizations, including increased efficiency, improved safety, and reduced costs. By leveraging the power of IoT technologies, organizations can transform their operations and gain a competitive advantage in today’s rapidly changing business landscape.

The benefits of IIoT

The Industrial Internet of Things (IIoT) is transforming the way that industrial organizations operate, offering a wide range of benefits and opportunities for businesses of all sizes. Some of the key benefits of IIoT include:

Improved operational efficiency and productivity

IIoT systems provide real-time data and analytics that can be used to optimize industrial processes, reduce waste, and improve efficiency. By using IIoT systems to monitor and control industrial processes, organizations can reduce the risk of errors and downtime, leading to improved productivity and profitability.

Increased safety and security

IIoT systems can be used to monitor industrial processes and equipment in real-time, detecting potential safety hazards and alerting operators to take action. Additionally, IIoT systems can be used to secure industrial facilities and equipment, preventing unauthorized access and reducing the risk of theft and vandalism.

Cost savings through predictive maintenance and reduced downtime

IIoT systems can be used to predict when maintenance is required, reducing downtime and increasing the lifespan of industrial equipment. By using IIoT systems to optimize maintenance schedules and reduce downtime, organizations can save significant costs over time.

Enhanced CX through personalized products and services

IIoT systems can be used to collect data on customer preferences and behavior, allowing organizations to offer personalized products and services that meet the unique needs of their customers. This can improve customer satisfaction and loyalty, leading to increased revenue and growth.

The benefits of IIoT are significant and wide-ranging. By leveraging the power of IoT technologies, industrial organizations can improve their operations, reduce costs, and gain a competitive advantage in today’s rapidly changing business landscape.

How can data science optimize performance in IoT ecosystems?

Challenges and risks of IIoT

While the Industrial Internet of Things (IIoT) offers many benefits, it also poses a number of challenges and risks that industrial organizations must be aware of. Some of the key challenges and risks of IIoT include:

Cybersecurity risks and concerns

As IIoT systems become more integrated into industrial processes, they also become more vulnerable to cyber attacks. Malicious actors can target IIoT systems to disrupt operations, steal sensitive data, or even cause physical harm. It is, therefore, essential for industrial organizations to implement robust cybersecurity measures, such as network segmentation, encryption, and access controls, to protect their IIoT systems.

Privacy and data protection issues

IIoT systems collect large amounts of data on industrial processes, equipment, and personnel. This data can include sensitive information such as personal data, trade secrets, and intellectual property. Industrial organizations must therefore ensure that they comply with data protection and privacy regulations, such as GDPR and CCPA, to protect this data from unauthorized access and misuse.

Lack of standards and interoperability

One of the challenges of IIoT is the lack of standardized protocols and interfaces. This can make it difficult for different IIoT devices and systems to communicate and work together. Industrial organizations must therefore ensure that their IIoT systems are designed with interoperability in mind and that they are able to integrate with other systems and devices as needed.

Need for specializedsSkills and expertise

The implementation and management of IIoT systems require specialized skills and expertise, including knowledge of networking, cybersecurity, data analytics, and industrial processes. Many organizations may not have these skills in-house and may need to partner with third-party vendors or consultants to implement and manage their IIoT systems.

The challenges and risks of IIoT require careful consideration and planning by industrial organizations. By implementing appropriate measures to address these challenges, organizations can minimize risks and reap the benefits of IIoT systems.

How industrial IoT market will shape the future?

The Industrial Internet of Things (IIoT) market is expected to continue to grow rapidly in the coming years, driven by advances in technology, increasing demand for connected devices, and the need for industrial organizations to improve efficiency and reduce costs. The IIoT market is expected to have a significant impact on the future of industrial operations and the global economy as a whole.

One of the key ways in which the IIoT market is expected to shape the future is through its impact on industrial efficiency and productivity. By providing real-time data and insights on industrial processes, IIoT systems enable organizations to optimize their operations, reduce downtime, and increase productivity. This can lead to significant cost savings and a competitive advantage for industrial organizations.

The IIoT market is also expected to have a major impact on safety and security in industrial environments. IIoT systems can be used to monitor and control industrial processes in real-time, detecting potential safety hazards and alerting operators to take action. Additionally, IIoT systems can be used to secure industrial facilities and equipment, reducing the risk of theft and vandalism.

Another way in which the IIoT market is expected to shape the future is through the development of new business models and revenue streams. IIoT systems enable organizations to collect and analyze vast amounts of data on industrial processes and customer behavior, providing insights that can be used to develop new products and services. This can lead to increased revenue and growth opportunities for industrial organizations.

Emerging technologies and advancements in IIoT

The IIoT market is constantly evolving, with new technologies and advancements emerging on a regular basis. Some of the key emerging technologies and advancements in IIoT include:

- 5G networks: The deployment of 5G networks is expected to revolutionize the IIoT market, enabling faster and more reliable data transmission and communication between IIoT devices.

- Artificial intelligence (AI): The integration of AI technologies with IIoT systems are expected to enable new levels of automation and decision-making, leading to further improvements in efficiency and productivity.

- Edge computing: Edge computing involves processing data at the edge of the network, closer to where the data is generated. This can help to reduce latency and improve real-time decision-making in IIoT systems.

- Digital twins: Digital twins are virtual representations of physical objects or systems. In the context of IIoT, digital twins can be used to simulate industrial processes and predict outcomes, enabling organizations to optimize their operations and reduce costs.

The emerging technologies and advancements in IIoT are expected to drive further growth and innovation in the market, enabling industrial organizations to achieve new levels of efficiency, productivity, and profitability.

The strategic value of IoT development and data analytics

Best IIoT solutions

There are many IIoT solutions available in the market, each with its own unique features and benefits. Some of the best IIoT solutions include:

Siemens MindSphere

Siemens MindSphere is a cloud-based IIoT platform that enables organizations to connect their machines, plants, and systems to the digital world. MindSphere provides a range of tools and services for data analytics, machine learning, and visualization, enabling organizations to optimize their operations and reduce costs. The platform is used in a variety of industries, including manufacturing, energy, and transportation.

Microsoft Azure IoT

Microsoft Azure IoT is a comprehensive IIoT platform that provides a range of tools and services for device management, data analytics, and visualization. The platform is built on Microsoft’s cloud infrastructure, enabling organizations to scale their IIoT systems as needed. Azure IoT is used in a variety of industries, including manufacturing, healthcare, and smart cities.

IBM Watson IoT

IBM Watson IoT is a cloud-based IIoT platform that provides a range of tools and services for device management, data analytics, and visualization. The platform is built on IBM’s cognitive computing technology, enabling organizations to analyze large amounts of data in real-time and make informed decisions. Watson IoT is used in a variety of industries, including manufacturing, energy, and transportation.

PTC ThingWorx

PTC ThingWorx is an IIoT platform that provides a range of tools and services for device management, data analytics, and visualization. The platform is built on PTC’s ThingModeler technology, enabling organizations to create digital twins of their industrial assets and optimize their operations. ThingWorx is used in a variety of industries, including manufacturing, energy, and transportation.

Amazon Web Services IoT

Amazon Web Services (AWS) IoT is a cloud-based IIoT platform that provides a range of tools and services for device management, data analytics, and visualization. The platform is built on AWS’s cloud infrastructure, enabling organizations to scale their IIoT systems as needed. AWS IoT is used in a variety of industries, including manufacturing, energy, and smart cities.

Overall, these IIoT solutions provide a range of tools and services that enable organizations to optimize their operations, reduce costs, and gain a competitive advantage in today’s rapidly changing business landscape. By leveraging the power of IoT technologies, industrial organizations can transform their operations and achieve new levels of efficiency and productivity.

Final words

Back to our original question: What is IIoT? IIoT systems provide real-time data and insights that enable organizations to optimize their operations, reduce costs, and gain a competitive advantage in today’s rapidly changing business landscape. From predictive maintenance to process optimization, IIoT offers a wide range of benefits that are driving its rapid adoption in industries such as manufacturing, energy, and transportation.

However, the challenges and risks of IIoT must also be considered, such as cybersecurity and data privacy concerns, lack of standards and interoperability, and the need for specialized skills and expertise. By addressing these challenges and leveraging the power of emerging technologies, industrial organizations can harness the full potential of IIoT and achieve new levels of efficiency, productivity, and profitability.